Posted 12th January 2021

Sometimes known as high-tension (HT) leads or Spark Plug Wires, Ignition leads carry an electrical current from

the ignition coil into the spark plugs, ultimately, lighting the fuel and air within the combustion chamber of the

engine. Comprised of conductive material surrounded by a silicone jacket for protection, Ignition Leads sit in

close proximity to the engine and must therefore be able to withstand dramatic temperature changes, caustic

chemicals and high physical forces. Lead cores can vary depending on vehicle manufacturer and the age of the

vehicle. The three technologies used are; Copper Cores, used mainly by German manufacturers, Wire Wound

(Reactive), commonly found in French vehicles, as well as Volvo & Saab, Resistive Cores, favoured by British,

Japanese and American manufacturers.

Ignition Leads are made from durable, low resistance materials, and tested to withstand the harsh environment

that they operate. Conductive materials in the leads will deteriorate, which in turn reduces the power able to

reach the engine, compromising the ignition process. Generally, this is caused be wear and tear, and leads

become worn out over time. Leads can also be affected more in winter months, as cold, damp conditions

increase the stress on the components whilst deterioration can be accelerated by water and salt ingress. Oil,

Coolant and Fuel Vapour can also cause oxidisation and corrosion in the connector contacts.

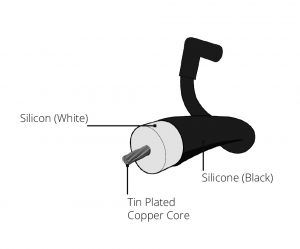

This consists of copper wire with negligible resistance

with double silicone outer combined with boots having an

inbuilt resistance to generate the required suppression.

The complex nature of copper core componentry makes

this technology more expensive than the other technology

types available. This type of cable is predominantly used

by German manufacturers.

The cable is made up of a carbon-coated fibreglass

core enclosed in stainless steel windings and double

silicone outer jacket. Engineered to meet or exceed

SAE specifications for radio frequency interference,

suppression comes from a magnetic field created when

current crosses the steel winding. This type of cable is

mainly used by French and Japanese vehicle manufacturers

as well as Saab and Volvo.

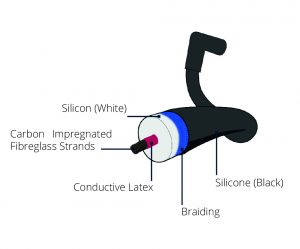

The cable contains a graphite coated fibreglass core which

is surrounded by a conductive latex coating and double

silicone outer. This is the simplest and most robust of the

cables used and works by providing resistance along the

length of the cable. This type of technology is typically used

by American, British and Asian vehicle manufacturers.

SMP Europe’s range of Original Fit Ignition Leadsets contain over 875 references making it the most

comprehensive range of OE fit sets available. Our portfolio can be purchased across all of our primary brands,

Intermotor, Lucas, High Volt and Electrospark. We are constantly monitoring the aftermarket to update our offerings

to ensure our customers remain up to date and have the sets they need for every repair.

To ensure optimum performance our lead sets are specifically tailored to each individual make and model

of vehicle. We specify the highest grade and quality materials possible, which meet or even exceed the OEM

specification, specifying the same cable technologies as offered by the original manufacturers.

Designed to meet or exceed OE performance, our leads are manufactured at our facility in Poland. The majority

of sets use 7mm or 8mm full silicone ad copper core cable, however our range also includes 5mm cable OE

sets to cover Japanese and Korean Vehicle parc.

To maximise radio suppression, resistance to temperature, water and oil degradation and chemical attack,

all our cable is manufactured with double silicone protection. All terminals are machine crimped to ensure

strong and reliable connections over a long service life. Spark plug boots and terminal covers are moulded

from silicone to give a water tight seal.

All of our leadsets are extensively tested. This includes, “Pull Off” tests, both hot and cold temperature testing,

checks on all terminals and connections and a high voltage saline solution immersion test to check for current

seepage.

Cables comprise of double silicone insulation and are manufactured using high quality Class F cable, tested to

meet international ISO3808/J2031 standards.